Free nursing study guides are invaluable tools, offering accessible learning resources for students navigating complex coursework and crucial exams like the NCLEX.

These guides, often available as PDF downloads, encompass a wide range of topics, from fundamentals to specialized areas like pediatrics and pharmacology.

Resources like Hibbing Community College LibGuides and comprehensive 600-page study guides provide extensive support, while Flash Notes focus on essential concepts.

The Importance of Accessible Resources

Accessible nursing study resources are paramount for students facing the financial burdens of education and the demanding rigor of the profession. Free study guides democratize learning, removing barriers to quality preparation for exams like the NCLEX and crucial coursework.

The availability of free PDF downloads, such as Nursing School Flash Notes covering 77 must-know topics, empowers students to focus on mastering essential concepts without incurring significant costs. Resources from institutions like Hibbing Community College further expand access to vital information.

These guides are especially beneficial for students balancing academic pursuits with work and personal commitments. They provide a flexible and convenient way to reinforce learning, review key material, and build a strong foundation in nursing principles. Ultimately, accessible resources contribute to a more equitable and prepared nursing workforce.

Overview of Available Free Guides

A diverse range of free nursing study guides are readily available online, catering to various learning needs and exam preparations. NCLEX Flash Notes, often found as free PDF downloads, concentrate on the 77 most critical topics for licensure success.

Students can also access comprehensive resources like the Hesi Fundamentals of Nursing Study Guide, offering detailed coverage of foundational concepts. Furthermore, extensive 600-page study guides provide in-depth exploration of numerous healthcare topics.

Online nursing libraries and databases, such as those highlighted by Hibbing Community College LibGuides, offer a wealth of textbooks, journals, and open educational resources. These guides span subjects from medical-surgical nursing to pediatrics and pharmacology, providing students with a multifaceted learning experience.

Types of Free Nursing Study Guides

Free nursing study guides encompass diverse formats, including NCLEX prep, fundamental concepts, pharmacology reviews, medical-surgical overviews, and specialized pediatric resources.

NCLEX Study Guides

NCLEX study guides are specifically designed to prepare aspiring nurses for the National Council Licensure Examination, a critical step towards professional licensure. Many free resources focus on the 77 “must-know” topics frequently encountered on the exam, as highlighted by NCLEX Flash Notes.

These guides typically offer concise summaries of key concepts, practice questions mirroring the NCLEX format, and rationales for both correct and incorrect answers. They aim to build confidence and test-taking strategies. Free NCLEX book PDF downloads provide a comprehensive review, covering all essential nursing areas.

Effective NCLEX study guides emphasize critical thinking, prioritization, and the application of nursing knowledge to clinical scenarios. Utilizing these resources alongside other study methods can significantly improve a candidate’s chances of success. Remember to focus on understanding the underlying principles, not just memorizing facts.

Fundamentals of Nursing Study Guides

Fundamentals of Nursing study guides lay the essential groundwork for a successful nursing education, covering core principles like patient safety, hygiene, vital signs, and basic nursing skills. Free resources, such as those found within the Hesi Fundamentals of Nursing Study Guide, provide a structured approach to mastering these foundational concepts.

These guides often include detailed explanations, illustrative diagrams, and practice exercises to reinforce learning. They emphasize the nursing process – assessment, diagnosis, planning, implementation, and evaluation – as a framework for providing patient-centered care.

A strong grasp of fundamentals is crucial for building a solid base for more advanced nursing courses. Utilizing free study guides allows students to supplement classroom learning and identify areas needing further attention. Focus on understanding the why behind each nursing action, not just the how.

Pharmacology Study Guides

Pharmacology study guides are indispensable for nursing students, given the critical role medications play in patient care. Free resources help navigate the complexities of drug classifications, mechanisms of action, side effects, and nursing considerations. Mastering pharmacology requires more than memorization; it demands understanding how drugs impact the body.

Effective guides often utilize mnemonics, drug charts, and practice questions to aid retention. Focus on key information like drug interactions, contraindications, and appropriate administration techniques.

While comprehensive textbooks are valuable, free study guides offer a convenient way to review and reinforce core concepts. Remember to critically evaluate the source and ensure information is current, as drug protocols can change. Prioritize understanding drug families and their common effects.

Medical-Surgical Nursing Study Guides

Medical-Surgical Nursing encompasses a broad spectrum of patient care, making dedicated study guides essential. Free resources can significantly aid comprehension of complex conditions, diagnostic tests, and treatment modalities. These guides often focus on prioritizing nursing interventions and understanding pathophysiology.

Look for materials that break down common medical-surgical diagnoses into manageable sections, covering assessment findings, nursing diagnoses, and expected outcomes. Practice questions are crucial for applying knowledge to clinical scenarios.

Effective guides emphasize the nursing process – assessment, diagnosis, planning, implementation, and evaluation – as it applies to medical-surgical patients. Remember to supplement free resources with textbooks and clinical experiences for a well-rounded understanding. Focus on critical thinking skills and patient safety.

Pediatric Nursing Study Guides

Pediatric Nursing demands specialized knowledge due to the unique physiological and developmental needs of children. Free study guides can be incredibly helpful in mastering this complex field, focusing on age-specific considerations and family-centered care.

Seek out resources that cover growth and development milestones, common childhood illnesses, and appropriate medication dosages. Understanding pediatric assessment techniques – often differing from adult approaches – is vital.

Effective guides will emphasize communication strategies for interacting with children of various ages and their families. Prioritize safety considerations, including injury prevention and recognizing signs of child abuse; Remember to supplement these free materials with clinical experiences and reputable textbooks to build a strong foundation in pediatric nursing practice.

Where to Find Free Nursing Study Guides

Free nursing study guides are readily available through online nursing libraries, Hibbing Community College LibGuides, and direct PDF downloads from various sources.

Nursing School Flash Notes and extensive 600-page guides are also accessible online.

Online Nursing Libraries & Databases

Online nursing libraries and databases represent a cornerstone for accessing free nursing study guides and a wealth of related educational materials. Institutions like Hibbing Community College offer comprehensive LibGuides specifically curated for nursing students, providing a centralized hub for research.

These LibGuides typically catalog access to academic journals, textbooks, and Open Educational Resources (OER), eliminating cost barriers to essential learning. Students can leverage these databases to find articles supporting coursework, explore different perspectives on nursing practice, and locate supplementary study materials.

Furthermore, many university and hospital systems maintain digital libraries with publicly accessible resources. Searching these databases using relevant keywords – such as “NCLEX review,” “pharmacology notes,” or “pediatric nursing” – can uncover valuable free study guides, practice questions, and clinical guidelines. Utilizing these resources effectively requires familiarity with database search functionalities and critical evaluation of source credibility.

Hibbing Community College LibGuides

Hibbing Community College LibGuides serve as an exceptional starting point for nursing students seeking free study guides and research assistance. This dedicated resource, accessible online, meticulously curates a collection of databases, books, academic journals, and textbooks relevant to nursing education.

The LibGuide’s strength lies in its organization, categorizing resources by specific nursing topics and course levels. Students can easily navigate to sections covering fundamentals, medical-surgical nursing, pharmacology, and more, discovering materials tailored to their current studies.

Beyond traditional resources, the LibGuide highlights Open Educational Resources (OER) – freely available online materials – offering cost-effective alternatives to expensive textbooks. Librarians at Hibbing Community College actively maintain and update the guide, ensuring the information remains current and reliable. This proactive approach makes it a consistently valuable tool for students pursuing nursing degrees and preparing for the NCLEX.

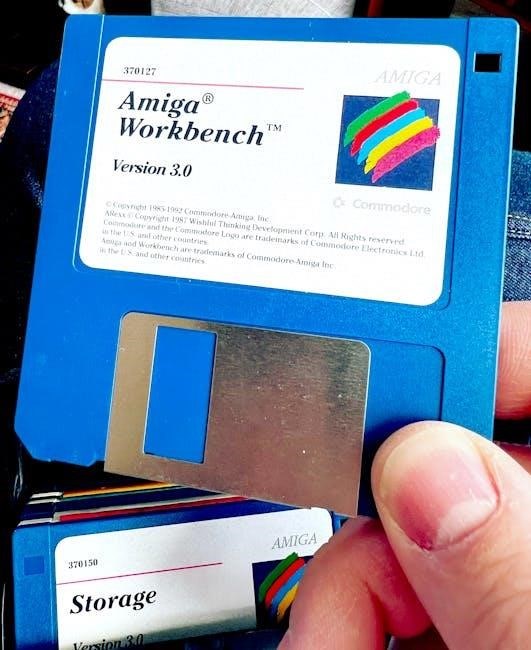

Free PDF Downloads

Free PDF downloads represent a cornerstone of accessible nursing education, offering students convenient and portable study materials. Numerous websites and educational platforms provide downloadable guides covering a spectrum of nursing topics, from foundational concepts to specialized clinical areas.

Nursing School Flash Notes, available as PDFs, are particularly popular, condensing 77 must-know nursing topics into concise, easily digestible formats. These notes are designed to boost study efficiency and reinforce key concepts. Similarly, comprehensive NCLEX Flash Notes (available as a book PDF) aid in exam preparation.

Students can also find extensive 600-page study guides in PDF format, offering in-depth coverage of various nursing subjects. While convenient, it’s crucial to verify the source and publication date of these downloads to ensure accuracy and relevance. Always critically evaluate the information presented.

Nursing School Flash Notes (PDF)

Nursing School Flash Notes, readily available as PDF downloads, are a highly effective study tool for nursing students. These condensed notes distill complex information into manageable, bite-sized pieces, focusing on the most crucial concepts and terminology.

Specifically, the 77 must-know nursing topics compilation is a popular resource, designed to enhance study efficiency and improve knowledge retention. These notes are structured to help students build a strong foundation and confidently tackle challenging coursework.

Similarly, NCLEX Flash Notes, also in PDF format, provide targeted preparation for the licensing exam. They cover essential exam content and help students identify areas needing further review. Utilizing these notes effectively involves active recall and spaced repetition techniques for optimal learning. Remember to supplement these notes with textbooks and other resources.

Comprehensive 600-Page Study Guides

Comprehensive 600-page study guides represent a substantial, freely accessible resource for nursing students seeking in-depth coverage of core concepts. Available as PDF files, these guides consolidate a vast amount of information, offering a single, extensive reference point for learning and exam preparation.

These guides typically encompass a broad spectrum of nursing topics, potentially including fundamentals, medical-surgical nursing, pharmacology, and more. While the sheer volume of material can be daunting, it provides a complete overview of essential knowledge.

Students can benefit from utilizing these guides as a primary study source or as a supplement to textbooks and other materials. Effective use requires a structured approach, breaking down the content into manageable sections and employing active learning strategies. Remember to verify the information’s currency, as content may require updates.

Utilizing Free Study Guides Effectively

Effective utilization involves creating a study schedule, employing active recall techniques, and leveraging spaced repetition for optimal retention, alongside integrating diverse resources.

Creating a Study Schedule

Developing a structured study schedule is paramount when utilizing free nursing study guides. Begin by assessing the volume of material covered in your courses and the NCLEX blueprint. Allocate specific time slots for each subject – Fundamentals, Pharmacology, Medical-Surgical, Pediatrics – ensuring a balanced approach.

Break down large topics into smaller, manageable chunks. For instance, instead of dedicating an entire day to “Cardiovascular Nursing,” focus on “Congestive Heart Failure” for a few hours. Prioritize topics based on their weightage in exams and your personal areas of weakness.

Incorporate regular breaks to prevent burnout and enhance information retention. Utilize tools like calendars or planning apps to visualize your schedule and track progress. Remember to be realistic and flexible, adjusting the schedule as needed to accommodate unexpected events or challenging concepts. Consistency is key to maximizing the benefits of your free study guides.

Active Recall Techniques

Active recall significantly boosts learning when using free nursing study guides. Instead of passively rereading material, challenge yourself to retrieve information from memory. Utilize Flash Notes – particularly the “77 must-know topics” – by attempting to answer questions before looking at the answers.

Practice explaining concepts aloud, as if teaching someone else. This forces you to organize your thoughts and identify knowledge gaps. Create self-testing quizzes based on the study guides, focusing on key definitions, disease processes, and nursing interventions.

Employ techniques like mind mapping or concept mapping to visually represent relationships between different concepts. Regularly test yourself on material from previous weeks to reinforce long-term retention. Active recall transforms free resources into powerful learning tools, enhancing understanding and exam preparedness.

Spaced Repetition for Retention

Spaced repetition is a highly effective learning strategy when utilizing free nursing study guides. This technique involves reviewing information at increasing intervals, strengthening memory over time. Don’t cram! Instead, revisit material from your NCLEX study guides or Fundamentals of Nursing resources a day later, then three days later, then a week, and so on.

Leverage Flash Notes by scheduling regular review sessions. Digital flashcard apps often incorporate spaced repetition algorithms, automatically adjusting review intervals based on your performance. This optimizes learning and minimizes forgetting.

Combine spaced repetition with active recall – test yourself each time you revisit the material. This dual approach maximizes retention, ensuring you can confidently apply your knowledge during clinical practice and on exams. Consistent, spaced review transforms free guides into lasting learning assets.

Combining Guides with Other Resources

Free nursing study guides are excellent starting points, but shouldn’t be your sole resource. Integrate them with textbooks, lecture notes, and clinical experiences for a comprehensive understanding. Utilize online nursing libraries & databases, like those found through Hibbing Community College LibGuides, to supplement guide content with peer-reviewed articles and in-depth analyses.

Pair NCLEX study guides with practice questions from reputable question banks. Complement Pharmacology study guides with drug cards and clinical simulations. Don’t hesitate to seek clarification from instructors or peers when encountering challenging concepts.

Remember, free PDF downloads and Flash Notes are tools to enhance, not replace, a well-rounded learning approach. A blended strategy maximizes knowledge acquisition and prepares you for success in nursing school and beyond.

Specific Free Resources & Their Strengths

NCLEX Flash Notes cover 77 must-know topics, while Hesi Fundamentals resources offer focused study aids. 600-page guides provide comprehensive coverage.

NCLEX Flash Notes – 77 Must-Know Topics

NCLEX Flash Notes represent a highly focused and efficient method for exam preparation, distilling crucial nursing concepts into easily digestible formats. These notes, frequently available as a free PDF download, concentrate on the 77 most frequently tested topics on the NCLEX examination.

This targeted approach allows students to prioritize their study efforts, ensuring they master the core knowledge essential for success. The notes are designed to boost confidence by providing a comprehensive yet concise review of key areas, including pharmacology, medical-surgical nursing, and fundamental nursing principles.

By utilizing these flash notes, aspiring nurses can effectively organize their study sessions, identify knowledge gaps, and reinforce their understanding of critical concepts. They serve as an excellent supplement to larger textbooks and study guides, offering a quick and effective way to review essential information before the big day.

The emphasis on “must-know” topics streamlines the learning process, making it ideal for students with limited study time.

Hesi Fundamentals of Nursing Study Guide Resources

Hesi Fundamentals of Nursing Study Guide resources are designed to build a strong foundation in core nursing principles, crucial for success in subsequent coursework and clinical practice. While comprehensive paid options exist, several avenues offer valuable, accessible support for students.

These resources often focus on essential topics like basic nursing skills, patient safety, medication administration, and infection control. A comprehensive user manual can aid in understanding the material, covering installation, operation, and maintenance of study techniques.

Students can find supplementary materials online, including practice questions, case studies, and review sheets, to reinforce their learning. Utilizing these free resources alongside textbooks and class notes allows for a more holistic understanding of fundamental concepts.

Mastering these fundamentals is paramount, and these guides provide a stepping stone towards advanced nursing knowledge and clinical proficiency.

Focus on Essential Nursing Topics

Free nursing study guides frequently prioritize essential nursing topics, recognizing the need for students to quickly grasp core concepts. These guides often concentrate on areas directly impacting patient care and frequently tested on examinations like the NCLEX;

Nursing School Flash Notes, for example, highlight 77 must-know topics, streamlining study efforts and maximizing efficiency; These resources typically cover subjects like vital signs, medication administration, infection control, and basic pathophysiology;

By focusing on these foundational elements, students can build a solid base of knowledge, enabling them to confidently tackle more complex nursing challenges. This targeted approach is particularly beneficial when preparing for standardized tests.

Effective guides emphasize practical application, linking theoretical knowledge to real-world clinical scenarios, ensuring a comprehensive understanding of essential nursing principles.

Limitations of Free Study Guides

Free nursing study guides may contain outdated information or lack personalized support, requiring critical evaluation to ensure accuracy and relevance for effective learning.

Potential for Outdated Information

Free nursing study guides, while incredibly helpful, often present a significant risk: the potential for containing outdated information. The healthcare landscape, and consequently nursing practice, is constantly evolving with new research, protocols, and pharmacological advancements.

Guides created even a short time ago may not reflect current best practices or the latest evidence-based guidelines. This is particularly crucial in areas like pharmacology, where drug dosages, interactions, and contraindications are frequently updated.

Relying on obsolete information could lead to incorrect clinical decisions and potentially compromise patient safety. Therefore, students must cross-reference information found in free guides with current textbooks, reputable online resources, and official clinical guidelines.

Always verify the publication date and source of the guide, and be prepared to supplement it with more up-to-date materials to ensure a comprehensive and accurate understanding of the subject matter. Critical thinking is paramount when utilizing these resources.

Lack of Personalized Support

A key limitation of free nursing study guides is the inherent absence of personalized support. Unlike structured courses or tutoring, these resources offer a one-size-fits-all approach to learning. They cannot adapt to individual learning styles, paces, or specific areas of weakness.

Students who struggle with particular concepts may find themselves without the tailored explanations or guidance needed to overcome those challenges. There’s no opportunity to ask clarifying questions or receive feedback on their understanding.

While guides can provide a solid foundation, they don’t replace the benefits of interactive learning environments or mentorship from experienced educators. Students must proactively seek out additional support – study groups, professor office hours, or online forums – to address their unique learning needs.

Self-direction and resourcefulness are crucial when utilizing free guides, as students are largely responsible for identifying and filling any gaps in their knowledge.

Need for Critical Evaluation

Free nursing study guides, while valuable, necessitate a critical and discerning approach from students. The open access nature means content isn’t always subject to the rigorous peer-review processes of traditional textbooks or academic materials.

Information can potentially be outdated, reflecting changes in medical practices or pharmaceutical guidelines. Students must verify the accuracy and currency of the material against reputable sources, such as current textbooks, professional organizations, and evidence-based practice guidelines.

It’s crucial to assess the author’s credentials and potential biases. Not all guides are created equal; some may prioritize brevity over comprehensiveness or present information in a simplified, potentially misleading manner.

Developing strong analytical skills is paramount. Students should cross-reference information, question assumptions, and seek corroboration from multiple sources to ensure a thorough and reliable understanding of the subject matter.